Full Line Service

From synthesis, purification, analysis, manufacturing to packaging, transfill; or joint development of new material to cater to each customer’s needs

About Us

Working with Taiwan’s precursor leader, Nanmat Technology, we have been offering products for thin film deposition in pan-semiconductor manufacturing industry since 2012. It's our mission to ensure our clients' success by enabling their production yield improvement and COO (Cost of Ownership) reduction.

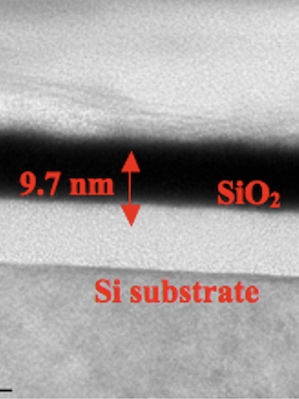

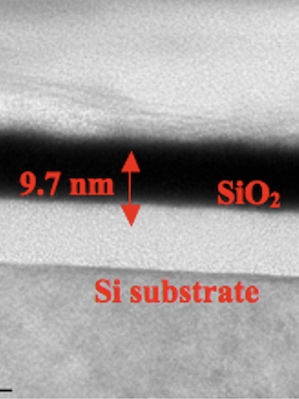

We not only bring clients with electronic-grade, high-purity, standard or tailored CVD (Chemical Vapor Deposition) and ALD (Atomic Layer Deposition) precursors, but also provide canister customization and smart canister with advanced level sensor. To help our clients to stay ahead of the game, we concurrently develop innovative materials that ease their transition to the next generation production.

Full line electronic materials - your partner in high k, metal gate and low k film deposition.

We source the optimal high quality stainless stell canister and tailored to meet your needs.

Ultra sound enabled liquid level sensor with fine tuned algorithm for precision measurement.

From synthesis, purification, analysis, manufacturing to packaging, transfill; or joint development of new material to cater to each customer’s needs

Equipped with full-line quality inspection tools. Awarded with BSI ISO 45001: 2018/ 14001: 2015; last certified in March 2024.

Canister ranging from 1.2-liter to 53-galon, we offer spec-compatible canister to drop in replace the existing ones.

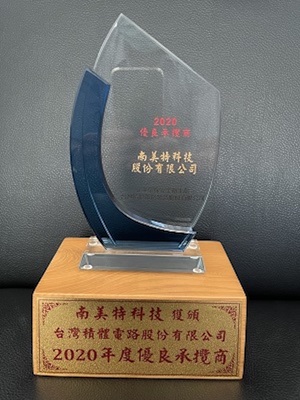

Nanmat Technology received Excellent Performance Awards from the global leading foundry in 2020 and 2021

| Application | Product Name | Purity |

|---|---|---|

| Dielectrics PMD/IMD | TEOS • TEPO • TMPO • TEB • TMB | >6N |

| Low K Dielectrics | • 4MS • OMCATS • DMDMOS |

>6N |

| High K Dielectrics | • TAETO (Ta2O5 Precursor ) |

>6N |

| Metal Gate and Interconnect Metal |

• TDMAT ( TiN Precursor ) • TiCl4 ( Ti /TiN Precursor ) • PDMAT ( TaN Precursor) • CCTBA (Co Precursor ) |

>6N |

| Low-Temp Nitride/Oxide | • HCDS • 3DMAS • BTBAS |

>6N |

| Dopants | • Trans DCE | >6N |

The system consists of a sensor probe and a control unit with a compact design. It senses the presence of liquid in the container based on the distribution of the ultrasonic field. The probe is separated from the control unit, does not require calibration, and is easy to install.

The probe is sealed in a stainless steel sleeve with no moving parts, longer life cycle while avoiding contaminateing the chemical. When in use, it does not need to be calibrated according to the density, dielectric constant, type, color and viscosity of the chemical to be tested. The probe is made of 316L stainless steel and is connected to the container through a ½” or ¾” VCR interface to prevent chemical leakage. The special process and algorithm design offers ±1.5 mm accuracy measurement. It can greatly increase the utilization rate of materials with low risk.